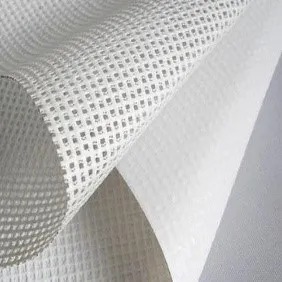

Manufacturing Materials

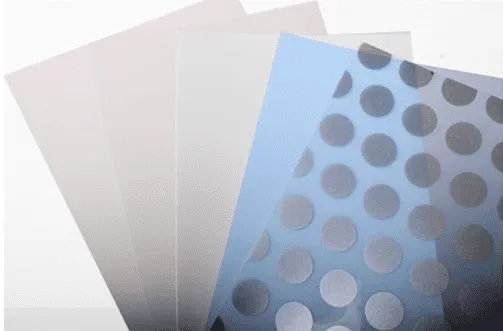

fabric

Al-Bereik is distinguished by the use of high quality fabrics in the manufacturing process, as it imports the fabrics according to the customer’s request. The company has specialists in the type of fabrics that is compatible with each client’s project. Regarding the fabrics, There are specifications presented to ensure the quality of the product and the production certificates. The company also gives the client a guarantee for years.

COMPANIES WE ARE COLLABORATING WITH

PTEF

about fabric

PTFE / Aramid Fabrics offer a surface texture similar to that of PTFE / Glass, but with an Aramid substrate that is stronger and more dimensionally stable than fiberglass. It is also more resistant to degradation from moisture exposure. There are 3 thicknesses of PTFE / Aramid fabric ranging from 5 mil to 17 mil.

In its original form, PTFE is a rigid substance that cannot be made into flexible, fabric-like materials. However, this substance can be added to other types of materials to make a fabric-like substance, and various types of fabrics can also be made with ePTFE, which is the stretched form of this linear polymer.

Specifications

PVDF

about fabric

PVDF fabric with good strength and flexibility is used in the construction of membrane structures. PVDF membranes are materials obtained by weaving fibers into fabric substrates and processing and repairing resins on both sides of the substrate. Central fabric substrate materials are divided into polyester fibers and glass fibers. In mechanical terms, each fabric substrate and coating material have the following functional properties: fabric substrate has tensile strength, tear strength, heat resistance and durability, fire resistance; coating material has weather resistance, antifouling, waterproof, light transmission.

PVDF membranes have the advantages of high thermal softness, low cracking, high cost performance, short production cycles and fast construction speed. In recent years, through continuous process and material improvements, weather resistance and antifouling properties have been improved. PVDF membranes that clean themselves have power hold more than 15 years .

ETFE

about fabric

The ETFE membrane thickness is only 0.2mm, which is a transparent film with high light transmission, light transmittance of up to 95%, and is not affected by ultraviolet light to ensure the natural light inside the building.

The quality is light, only 0.15-0.35 kg per m2, and corrosion resistance, negative pressure resistance, fire protection standards reach B1, DIN4102 grade.

High anti-fouling, easy to clean, service life of at least 25-35 years, and can also recycle materials. Waste membrane can be reused to produce new membranes.

PVC

about fabric

PVC is one of the most commonly used plastics in the world. Global polyvinyl chloride use is above 35 million tons per year, and the demand is constantly growing. At a global level, PVC usage grows by an average of 5% per year, with higher growth rates within countries in the developing world.

Because of its versatility, PVC fabric is an ideal solution for many different applications. In the European Union, about 8 million tons of PVC products are manufactured every single year. Annual European consumption of PVC resin totals 6.5 million tons – 15% of all plastics used in Europe.

PVC is sometimes known as ‘Vinyl’ in Europe and more commonly so in the US. In Europe, ‘Vinyl’ usually refers to certain specific flexible applications, such as flooring, decorative sheets and artificial leather, among other applications.

what is it used for?

Automotive: Vinyl products are produced to customer specifications and can be modified to meet tier 1 processing requirements. PVC products can then be used throughout the car interior for instrument panels, door casings, seating, gear lever gaiters, headliners, load space covers and other components. From a design perspective, vinyl can be produced to imitate leather, fabrics and even carbon fiber making it the ideal solution for multiple interior trim applications.

Mass Transportation (Bus, Rail): Given the high usage environment of the mass transportation industry, robust surface performance is key and vinyl can offer an unprecedented level of grain, color and style. Vinyl products offer a real alternative to more traditional leather or wool based surfaces, whilst offering class-leading seat wear and stain resistance. Offering a hygienic, design led finish expected from public transport.

Marine and Off-Highway: Vinyl is the perfect choice for marine applications as it is easy to maintain, waterproof and inhibits bacterial growth with the addition of biocides. Vinyl is the optimum solution for the upholstery of powerboats to yachts to cruise ships. Vinyl products are suitable for exterior and interior seating & upholstery as well as trim and cabin headliners.

Healthcare: Vinyl products have been the obvious choice for healthcare upholstery for many years due to its durability, cleanability and its resistance to the growth of mold and mildew. If a robust care routine is adhered to, there is no reason why vinyl upholstery cannot last for many years.

Hospitality: PVC fabrics in a number of different designs and effects are ideal for the Leisure and Hospitality sector. Great designs can be combined with durable and hygienic PVC fabrics.

Residential Care: PVC fabric has for many years been the premium choice for creating practical and attractive residential décor, engineered to be stain and abrasion-resistant, fire-retardant and antimicrobial there is no better fabric for this application.

Leisure: The durability and anti-bacterial qualities of PVC fabric make it the ideal choice for gym equipment and health club environments particularly as it is stain resistant and easy to clean.

Polyvinyl chloride is a thermoplastic product made of 57% chlorine (developed from industrial grade salt) and 38% carbon (predominantly from oil/gas via ethylene). PVC can be recycled by breaking it down into small chips, impurities removed and the product refined to make pure PVC. It can be recycled roughly seven times and has a lifespan of around 140 years.

PVC is made softer and more flexible by the addition of plasticizers which also dramatically improves its performance characteristics.

As PVC is heated to soften during the coating or molding process, like any plastic PVC is formulated to resist damage my heat which allows users to thermoform PVC parts.

السيارات: يتم إنتاج منتجات الفينيل وفقًا لمواصفات العميل ويمكن تعديلها لتلبية متطلبات معالجة المستوى .يمكن بعد ذلك استخدام منتجات PVC في جميع أنحاء الجزء الداخلي للسيارة لألواح العدادات وأغلفة الأبواب والمقاعد وأذرع ذراع ناقل الحركة وبطانات السقف وأغطية مساحة التحميل والمكونات الأخرى. من منظور التصميم ، يمكن إنتاج الفينيل لتقليد الجلود والأقمشة وحتى ألياف الكربون مما يجعله الحل الأمثل لتطبيقات الزخرفة الداخلية المتعددة.

النقل الجماعي (الحافلات والسكك الحديدية): نظرًا لبيئة الاستخدام العالية لصناعة النقل الجماعي ، يعد الأداء القوي للسطح أمرًا أساسيًا ويمكن أن يوفر الفينيل مستوى غير مسبوق من الحبوب واللون والأناقة. تقدم منتجات الفينيل بديلاً حقيقياً للأسطح التقليدية المصنوعة من الجلد أو الصوف ، بينما تقدم مقاعد رائدة في فئتها ومقاومة للبقع. تقدم تشطيبات صحية وتصميمية متوقعة من وسائل النقل العام. للحصول على أفضل عرض منتج ممكن ، يمكن لبعض الشركات المصنعة مطابقة منتجات الفينيل لأنماط موكيت المعقدة.

البحرية والطرق الوعرة: الفينيل هو الخيار الأمثل للتطبيقات البحرية حيث يسهل صيانته ومقاومته للماء ويمنع نمو البكتيريا مع إضافة المبيدات الحيوية. الفينيل هو الحل الأمثل لتنجيد الزوارق السريعة لليخوت والسفن السياحية. منتجات الفينيل مناسبة للمقاعد والمفروشات الخارجية والداخلية بالإضافة إلى البطانات الأمامية والمقصورة.

الرعاية الصحية: كانت منتجات الفينيل هي الخيار الواضح لمفروشات الرعاية الصحية لسنوات عديدة بسبب متانتها وقابليتها للتنظيف ومقاومتها لنمو العفن والعفن. إذا تم الالتزام بروتين رعاية قوي ، فلا يوجد سبب يمنع تنجيد الفينيل لسنوات عديدة.

الضيافة: تعتبر الأقمشة البلاستيكية في عدد من التصاميم والتأثيرات المختلفة مثالية لقطاع الترفيه والضيافة. يمكن الجمع بين التصميمات الرائعة والأقمشة البلاستيكية المتينة والصحية.

الرعاية السكنية: كان نسيج PVC لسنوات عديدة هو الخيار الأفضل لإنشاء ديكور سكني عملي وجذاب، حيث تم تصميمه ليكون مقاومًا للبقع والتآكل، ومثبطًا للحريق ومضادًا للميكروبات ، ولا يوجد قماش أفضل لهذا التطبيق.

الترفيه: المتانة والصفات المضادة للبكتيريا لنسيج PVC تجعله الخيار المثالي لمعدات الصالة الرياضية وبيئات النوادي الصحية خاصةً لأنه مقاوم للبقع وسهل التنظيف.

البولي فينيل كلوريد هو منتج لدن بالحرارة مصنوع من 57٪ كلور (مطور من ملح صناعي) و 38٪ كربون (في الغالب من النفط / الغاز عبر الإيثيلين). يمكن إعادة تدوير PVC عن طريق تقسيمه إلى شرائح صغيرة وإزالة الشوائب وتنقية المنتج لصنع PVC نقي. يمكن إعادة تدويره سبع مرات تقريبًا ويبلغ عمره الافتراضي حوالي 140 عامًا.

أصبح PVC أكثر نعومة ومرونة من خلال إضافة الملدنات التي تعمل أيضًا على تحسين خصائص أدائها بشكل كبير.

نظرًا لأن PVC يتم تسخينها للتليين أثناء عملية الطلاء أو التشكيل ، مثل أي بلاستيك بولي كلوريد الفينيل يتم صياغته لمقاومة التلف الحراري الذي يسمح للمستخدمين